Bridges design standards

There are many factors in designing and engineering efficient bridge design that an engineer must consider when designing bridges or a new highway. The good and efficient design of the bridge road is based on accurate knowledge of the properties of the materials used and the design loads, using well thought out engineering principles and reliable and developed computer software. It should also take into account the interaction with the Earth and the environment.

Bridge definition: A structure that extends horizontally between the supports, and its function is to carry vertical loads. The typical bridge is very simple – two supports beam lifting – but engineering problems that must be overcome even in this simple form are inherent to each bridge: the supports must be strong enough to hold the structure, and the period between the supports should be strong enough to withstand the loads. Distances are generally extended as possible; long, justified periods extend where good foundations are limited – for example, on estuaries in deep waters.

Designing the bridge that best serves the public interest has a triple goal: to be as efficient, economical, and elegant as possible. Efficiency is a scientific principle that places value on reducing materials while increasing performance. Economy is a social principle that puts value in reducing construction and maintenance costs while maintaining efficiency. Finally, elegance is a symbolic or visual principle that places value on the personal expression of a designer without compromising performance or economics. There is not much disagreement about what constitutes efficiency and economics, but the definition of elegance has always been controversial.

Engineers should think about how to make the structure beautiful. This last principle recognizes the fact that engineers have many possible options that are nearly equally efficient and economical, and therefore they can express their aesthetic ideas without adding material or large costs

In general, bridges can be divided into two categories: standard bridges, or bridges with a unique design on rivers, stalking, or estuaries.

Bridges design elements

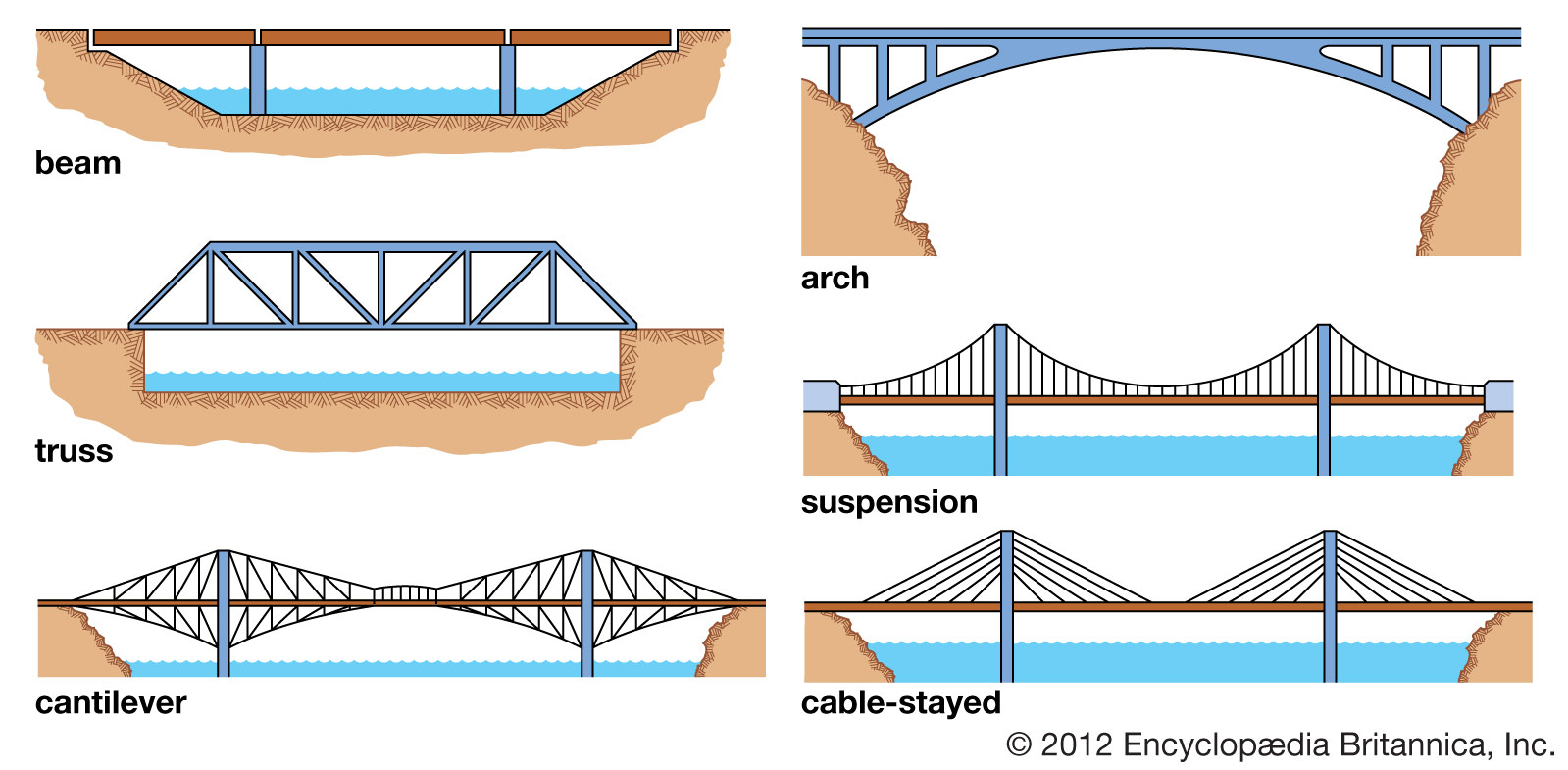

There are six basic bridge shapes: beam, truss, bow, suspension, cantilevered, cable.

Beam Bridge: It is the most common bridge shape. A beam that holds vertical loads by bending. When the beam bridge is bent, it is subject to horizontal pressure at the top. At the same time, the bottom of the horizontal tension beam is exposed. The supports carry loads from the beam by pressing vertically on foundations.

When a bridge consists of only two beams, it is simply called a supported bridge. If two or more columns are held together tightly over the supports, the bridge becomes continuous.

Truss Bridge: A single bridge is similar to a supported beam simply because it holds vertical loads by bending. Bending leads to compression in the upper cords (or horizontal organs), tension in the lower cords, and tension or pressure in the vertical and diagonal organs, depending on their direction. Gables are commonly used because they use a relatively small amount of material to carry relatively large amounts.

Arched bridge: mainly carries loads by means of pressure, which exercises on the basis of both vertical and horizontal forces. Therefore the foundations of the arch should prevent both vertical stability and horizontal sliding. Despite the more complex foundation design, the structure itself usually requires less material than a beam bridge in the same period.

Suspension Bridge: Holds vertical loads through tense curved cables. These loads are transmitted both to the towers, which they carry by perpendicular pressure to the ground, and to the anchors, which must withstand internal and vertical clouds at times. The suspension bridge can be viewed as an inverted arc in a tense situation with only pressurized towers. Since the surface is suspended in the air, care should be taken to ensure that it does not move excessively under load. Consequently, the surface must be either heavy, solid, or both.

Cantilever Bridge: The beam is said to protrude when it appears outside, supporting only at one end. The cantilever bridge generally consists of three distances, which are fixed by the external stretches of the beach and the descender outside the channel to be crossed. The central range lies on cantilever arms extending from outer distances; it carries vertical loads like a simply supported beam or gears – that is, due to the forces of tension in the lower ropes and pressure in the upper ropes. The lights carry their loads by tension in the upper ropes and pressure in the lower limbs. Inner constellations carry these forces by pressing on the foundation, while external constellations carry these forces by tension to distant foundations.

Cable Bridge: The bridges that remain with the cable withstand the main vertical loads with roughly straight diagonal cables. The towers transfer the forces of the cables to the foundations through vertical pressure. The tensile forces in the cables also placed the surface in horizontal pressure.

The four basic materials used to build bridges

They are wood, stone, iron, and concrete. Of these, iron had the most influence on modern bridges. From iron, steel is made, and steel is used to make reinforced concrete and stress. Modern bridges are built almost exclusively from steel, reinforced concrete and prestressed concrete.

Wood is relatively weak in both stress and tension, but it has always been widely available and inexpensive. Wood has been used effectively for small bridges that carry light loads, such as pedestrian bridges. Engineers are now incorporating rafters and wooden arches into some modern bridges.

The stone is strong in compression but weak in tension. It was mainly applied to brackets, sidewalks and supports.

Iron and steel

The first iron that was used during the Industrial Revolution was cast iron, which is strong in compression but weak in tension. Wrought iron, on the other hand, is strong in compression like cast iron, but also has a much greater tensile strength. Steel is an additional improvement of iron and is stronger than any iron in both stress and pressure. Steel can be made with varying strengths, as alloys are five times stronger than others.

Concrete: An artificial stone made of a mixture of water, sand, gravel and a binder such as cement. Like stone, it is strong in pressure and weak in tension. Concrete with steel bars is so embedded in reinforced concrete. Reinforcement allows the use of less concrete because steel holds all tension; also, concrete protects steel from corrosion and fire.

Construction work

All bridges need to be secure in the foundations and supports. In the case of a typical bridge beam bridge with one support in the middle, construction begins with the pouring of the concrete foot of the dock and the rotor. When the soil is particularly weak, wooden or steel piles are pushed to support the surfaces.

After the pavements and concrete have sufficiently tightened, the superstructure of the concrete or steel begins to be erected. Steel beams are generally made at the factory, shipped to the site, and placed in place by the cranes. For short periods, steel beams are usually formed as one unit. On site, they are placed in parallel with each other, with temporary shapes between them so that a concrete surface can be poured on top. The beams usually have welded metal parts on their upper edges, where concrete is poured around. These pieces provide a connection between the beam and slab, thus producing a composite structure.

Arch bridge design:

Braces are usually fabricated on site. After building the supports (and sidewalks, if the bridge is multilayer), fake works are created. To obtain a concrete arch, metal or wood shapes and forms adhere to cast concrete and are removed later. For steel arches, cantilever method is standard. Each side of the arch is designed towards the other side, supported by higher temporary cables until the ends meet. At this point the arc becomes self-supporting, and the cables are removed.

Design of suspension bridges:

When bridges requiring sidewalks are built on a water body, the foundations are created by submerging the caissons in the riverbed and filling them with concrete. Caesars are large boxes or cylinders made of wood, metal, or concrete. In the case of suspension bridges, the towers are built over the Caissons. The first bridge suspension towers were stone, but now they are either steel or concrete. After that, the anchors are built on both ends, usually of reinforced concrete with integrated steel eyebrows to which the cables will be attached. The eyebrow is the length of the metal with a hole (or “eye”) at the ends. The cables for the first hanging bridges were made of wrought iron connected poles; now, however, the cables are generally made of thousands of steel wires collected together at the construction site. Yarn is made by rope reels that hold each wire across the top of the towers to the back anchor and back. Then the wire is assembled and covered to prevent corrosion. When the cables are complete, the suspensions are suspended, and finally the surface is installed – usually by floating the surface sections on the ships, lifting them with cranes, and securing them to the brackets.

The main mission of the bridge is to carry traffic loads: heavy trucks, cars and trains. Engineers should estimate the traffic load. In short periods of time, the maximum conceivable load can be achieved – meaning that at distances less than 30 meters (100 feet), four heavy trucks may cross at the same time, two in each direction. In periods longer than a thousand meters or more, bearing natural forces such as wind cause two important loads, one called constant and the other dynamic. Fixed wind load is the horizontal pressure that attempts to push a side bridge. The dynamic wind load leads to vertical movement, which creates oscillations in any direction.

Modern bridges should also withstand natural disasters such as tropical cyclones and earthquakes. In general, earthquakes are better resisted by structures that carry as light weight as possible, because the horizontal forces created by the acceleration of the Earth are proportional to the weight of the structure. (This phenomenon is explained by Newton’s basic law of force equal to the acceleration of mass times.) It is generally preferable for the bridge to be dynamically designed so that it contains a small solid material facing the wind, so that it can pass through or around the bridge. Without placing dangerous oscillations.

Read also; Airport design and factors to consider in design

العربية

العربية