The use of wood in building design

The use of wood in building design

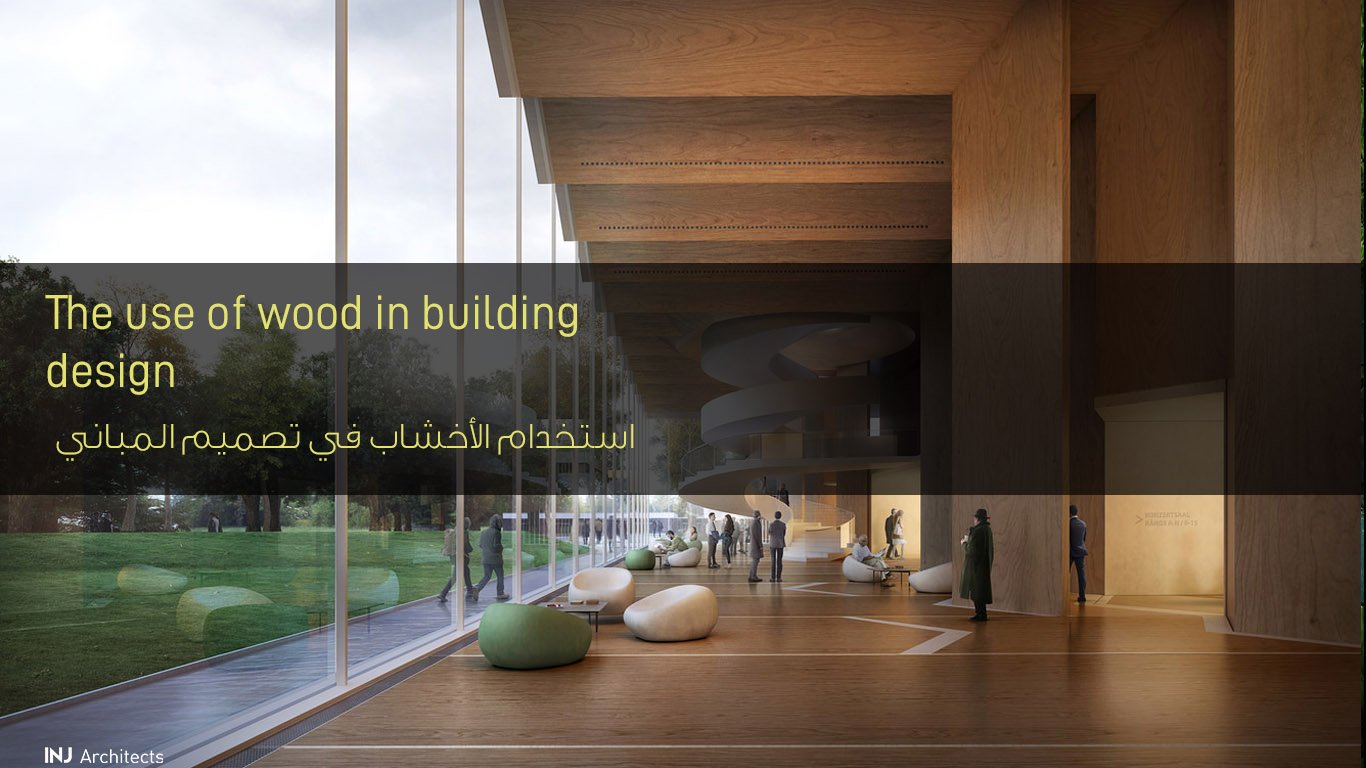

Progression to the twenty-first century as it allows architects to explore and present an increasing number of sustainable methods of architecture and building industry. One of these methods is the use of wood in building design.

While concrete and steel had previously been used extensively throughout the building and construction industry, architects are now beginning to realize the importance of new technologies, such as wood, and their use for construction, sustainability and cost-effective purposes.

Some may say that the use of timber in building design is ridiculous considering that timber is arguably the oldest building material. But new innovations in structural wood design have inspired a range of frontier plans for old materials, including everything from bridges to skyscrapers. More importantly, these designs are on the right path towards their realization, and they comply with building codes that many see (mistakenly) as being restricted to the point of impossibility.

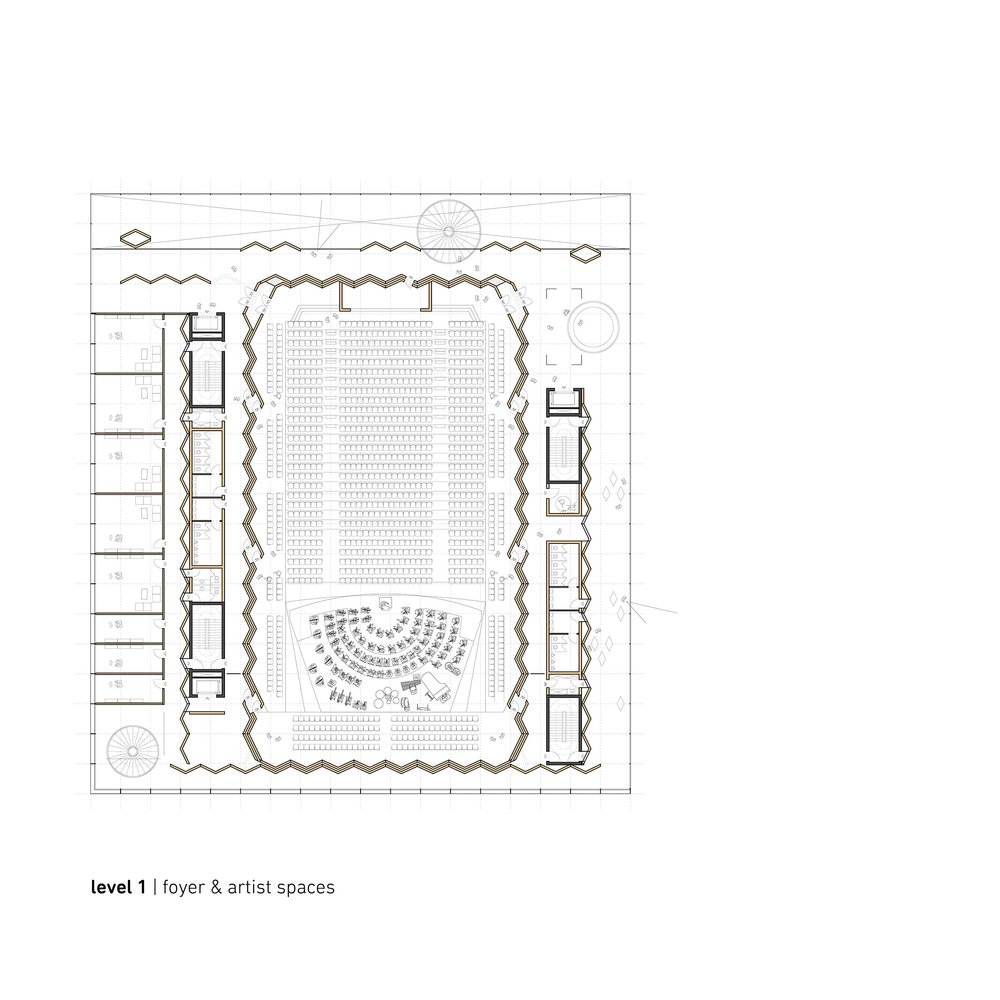

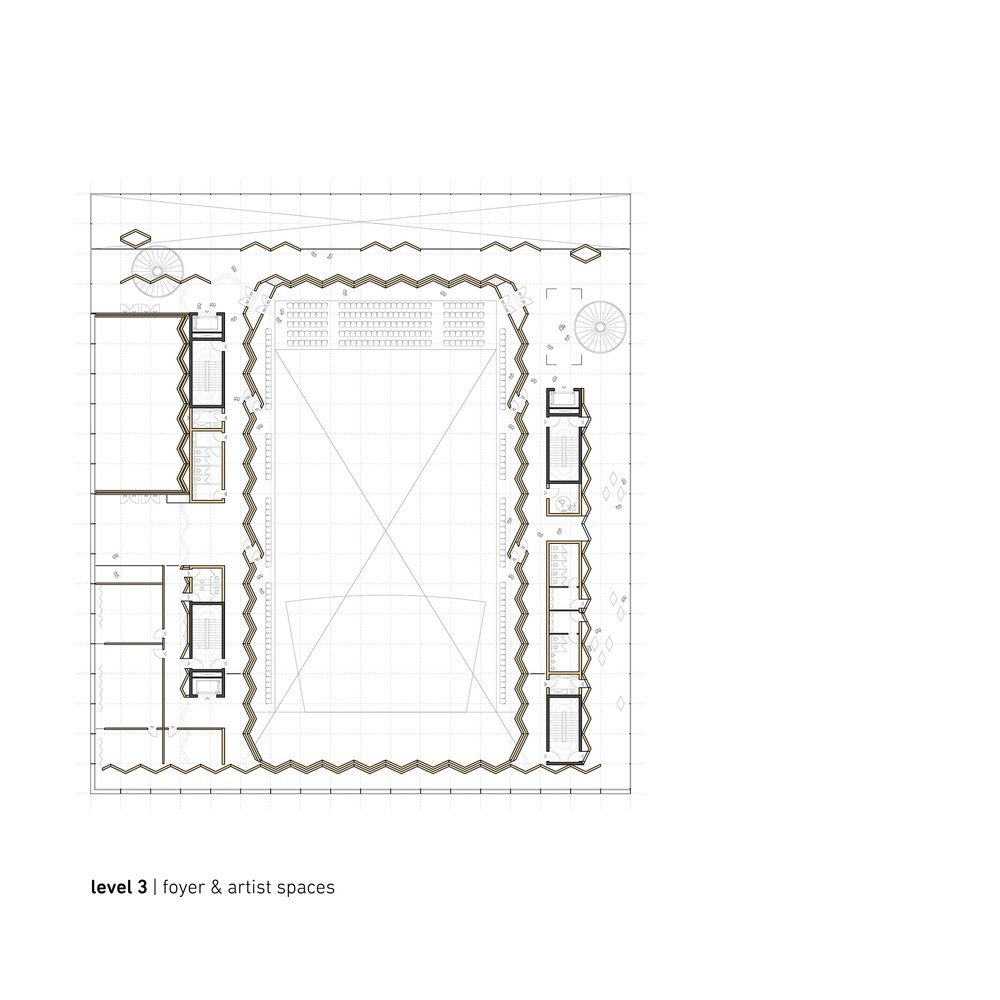

In a recent international competition, architects Jill Ritsen and Stephan Marcus Albrecht were chosen from among 20 Meistersingerhalle World Cup finalists in Nuremberg, Germany. Architects collaborated with Bollinger-Grohmann engineers, cross-polar climate engineers, and sound specialists such as theater projects, to design what would be the first building in a concert hall in the world to be built using cross-laminated timber (CLT) in Nuremberg

The concert hall is located in the Bavaria region of Germany, which is known as one of the largest forested areas in Europe, providing types of wood for construction purposes. This convenient location of the materials from the project allowed it to be sourced locally and efficiently. Timber will be manufactured off site at factory setting and will be transported during the construction phase to the site, resulting in a rapid assembly of CLT panels and a cost-effective and time-saving construction process. The ready-made CLT units used for design will be produced using CNC machines and industrial robots inside the factory.

The shape of the building consists of a upper block designed with CLT units, a basement and a concrete core. While timber construction could have been used initially, there is still debate in the way of thinking about this within the industry for fire purposes, the design continued closely accelerating the construction of the CLT, and engineers Bollinger Grohmann managed to achieve 9 meters of sulfate to the main lobby areas, usually It is achieved only through the use of steel and reinforced concrete. To achieve this result, engineers used innovative details of the sleeve joint on the glass façade that absorbs, creates and moves the timber structure over a period of time.

The building program directs itself around the central concert hall and is designed from the inside out. The concert hall is the benchmark for the building’s program and structure, starting with large wooden windows that go out and frame support areas and lobby areas. The architectural result can be understood as a homogeneous group of woods, as walls, ceilings, and columns follow the same organizational logic throughout the building. To continue the internal and external logic, the concert hall is closed with a glass façade, allowing the building to be understood from all sides, exposing its internal elements to the public.

For sound insulation purposes, concert halls are usually designed using a box-in-box system. This construction method usually indicates that the main building’s structure becomes independent of the acoustically isolated secondary structure in noise-prone areas. Theater Consultants acoustics have developed an alternative approach whereby a two-layer CLT wall is constructed of 150 mm CLT slabs with rock wool insulation trapped between them. This allows heavy blocks of wood to provide the same acoustic quality and vibration absorption as concrete.

Among the group of notable new MGA (Michael Green Architectur) wooden structures (Architect), a project in Minneapolis carried out large quantities of wood, completed in 2016. The project is a broad-windowed structure in the center The city, by breaking the myth that structural timber projects cannot produce open spaces facilitated by steel structures in addition to the low carbon content in the building as it is estimated to be 30% lighter than steel and 60% lighter than concrete.

Also, in downtown Atlanta, there is a 7-storey building at an altitude of 230,000 square feet. It operates around the clock on weekdays as offices, restaurants, and stores. The interior combines the warmth of heavy wood with modern first-class amenities. Tenants will have access to the ground floor stores, cooperation areas, a fitness center, outdoor spaces on each floor, and a rooftop lounge. T3 West Midtown is named the first new Wired Platinum Certified development in Atlanta.

Read also: Considerations for a healthy environment in urban design – Netherlands

But while both structures boast impressive design and sustainability credentials, the most impressive are yet to come. T3 Goose Island is located in Chicago, and will (upon completion) be the largest collective timber structure in the United States. This wooden structure office building will boast, plus ample office space, bicycle storage, 275 parking spaces, retail ground floor, shared lounges, fitness center, private balconies, and a shared roof terrace.