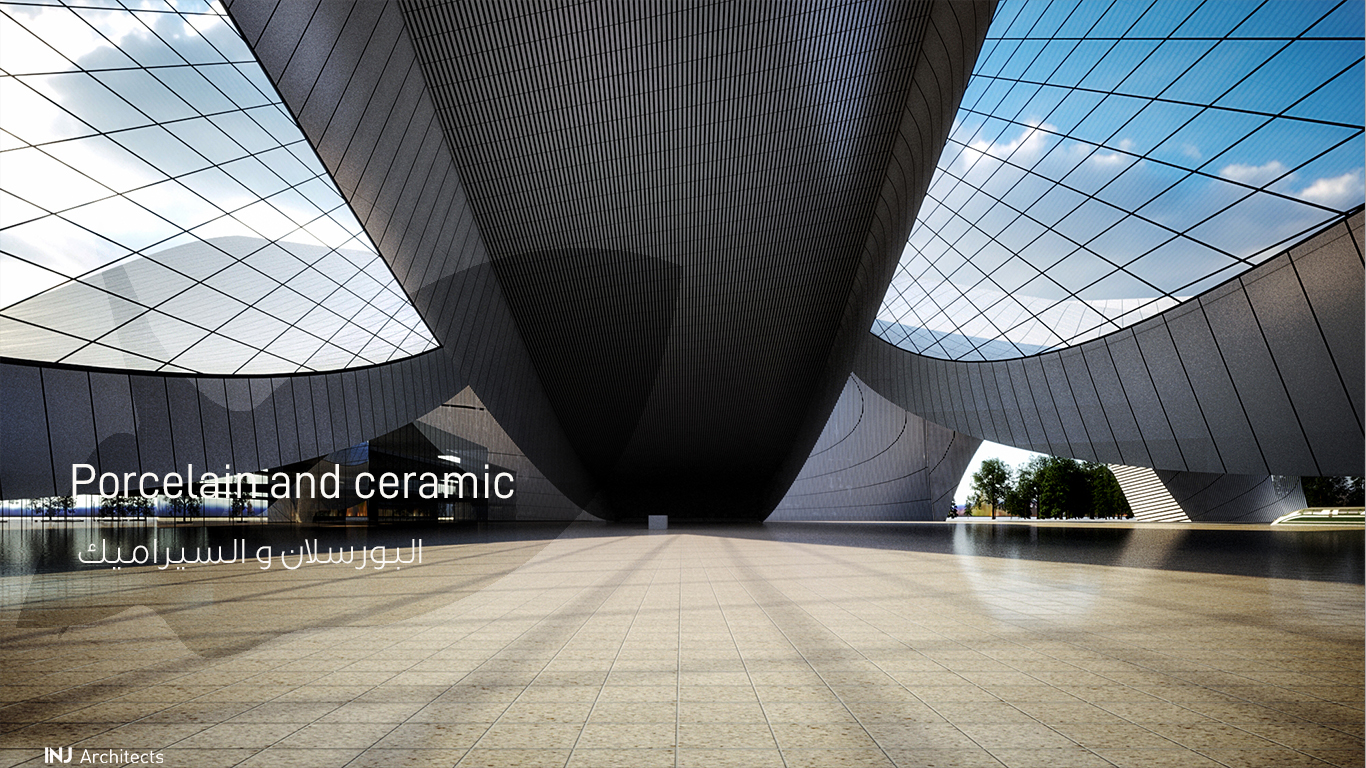

Porcelain and ceramic

Porcelain and ceramic The difference between them and the methods of their use:

what is the difference between Porcelain and ceramic and the methods of their use?

Porcelain:

it is an industrial product that results from mixing calcareous soils and crumbs from granite and marble crusher that results from the crushing of rocks. To the furnaces under very high temperatures.

Method of making and producing porcelain:

1- Granite and marble remains are extracted from the rocks and treated until they become a mixture.

2- Knead the mixture and add stabilizers such as white cement, then put it in molds according to the shape, size, and thickness required for production.

3- The molds shall be inserted into the ovens under a high temperature not less than 1,200 ° C.

4- Take out the molds for cooling, then paint them with different colors and allow them to dry, then place the required drawings on them via a layer called Ghail.

5- Insert porcelain molds again for the kiln, but with a temperature of fewer than 700 degrees Celsius, and this is determined by the thickness of the porcelain mold that is produced.

* Porcelain features:

1-Porcelain is characterized by its wonderful designs and distinctive look.

2- Porcelain is considered to be the most advanced and used industry, as it is considered more powerful, hard and durable than any type of ceramics.

3- It is characterized by being water-resistant and longevity.

4- The porcelain surface has a more smooth surface than ceramic.

5- Porcelain is more resistant to scratch than ceramic.

6- Porcelain has a greater volume and density than ceramics.

7- Porcelain thickness is relatively large for ceramics.

8- Porcelain is used in floors, walls and as destinations for companies and homes.

* Porcelain defects:

Heavy in weight, difficult to cut due to its strong hardness.

It is considered a high price relative to any other type in the market, in addition to that it requires higher expenses in installation.

Porcelain tiles are divided into two types:

1- Smooth and is very shiny.

2- It is rough and has a lower shine.

Ceramics:

Ceramics are made of clay loam with a very light texture.

Ceramic manufacturing and production method:

1- Kneading clay and clay with some stabilizers such as white cement, then it is formed and placed in molds according to the required thickness and size.

2- Press and press the molds according to the size of the ceramic being produced.

3- Inserting the molds into the oven under a temperature not less than 700 degrees Celsius.

4- Take the molds out of the oven and paint them with light ceramic material.

Ceramic Characteristics and Disadvantages:

1- The ceramic surface is moderate in texture, as it prevents skating.

2- Ceramics are affordable and cost-effective for porcelain.

3- Ceramic is used to make floors and walls, and it is less dense than porcelain.

4- Ceramic is used as interior decoration for your home.

5- Ease of cleaning ceramics in the easiest way.

6- It is characterized by its ability to withstand high temperatures.

7- The tiles, with its dark and pale colors, give more areas.

Ceramic defects:

1- Ceramic has a lower volume than porcelain.

2- Less durable and less scratch-resistant.

3- Ceramic floors do not absorb loud sound.

4- Ceramic is considered one of the lands that do not maintain temperature.

* Types of ceramics:

1- Highly absorbent ceramic, with a thin mold with open features and sound transmitted through it.

2- Ceramics have low absorption of water, where the mold is of high density and features are closed and the sound is transmitted through it in a resonant manner.

* Steps to follow when using porcelain and ceramic:

1- Measuring the area you want to tile and knowing the areas accurately.

2- Maintaining the appropriate slope when tiling, so that the slope is (1%) to facilitate the flow of water and prevent moisture.

3- Ensure the roughness of the porcelain and ceramic parts, to ensure good adhesion.

4- A good adhesive must be chosen to fill the blanks well.