yuji tanabe architects’ TWINS-MDF chairs fit together like a puzzle

TWINS-MDF, a spinoff of yuji tanabe architects’ 2004 work

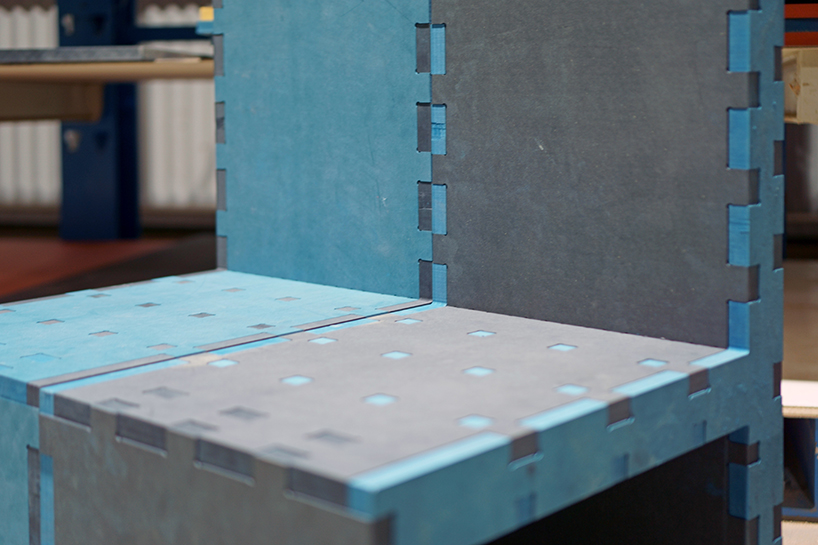

Japanese practice Yuji Tanabe Architects has just launched a spinoff of its TWINS chair project, developed 18 years ago as two stackable stainless steel seats that fit into one another like a puzzle. The 2022 version, titled ‘TWINS-MDF,’ takes the original design one step further by using Medium Density Fiberboard — a composite material made of wood fibers and synthetic resin adhesive — to create the ‘Frame’ and ‘Surface’ chairs.

Like their name suggests, ‘Frame’ is built to serve as the outline of ‘Surface,’ complementing each other like solid and void. Moreover, due to the uneven top of each chair’s back plate, it’s possible to connect them laterally like a bench.

all images via Yuji Tanabe Architects

a mass/void chair set with a high yield rate

To produce the ‘TWINS-MDF’ set, the team at Yuji Tanabe Architects extracted the backboard of ‘Surface’ from the inside of ‘Frame’ using EMARF’s Shop Bot (CNC router). The process required first a repeated study of the manufacturable range, drill width, and position interference of the joints. ‘It’s like creating a puzzle while searching for the greatest common divisors of each,’ explains the practice.

Finally, by studying each chair’s Medium Density Fiberboard trimmings, Yuji Tanabe Architects has achieved a high yield rate, exceeding 70%, with remarkably few offcuts in the standard Japanese 4×8 board size (1219x2438mm). The yield rate is the ratio of sawn timber obtained to raw wood. The higher the number, the lesser the waste.

‘TWINS-MDF’ chairs produced at two different scales

‘TWINS-MDF’ chairs produced at two different scales

‘Surface’ and ‘Frame’ represent a relationship of mass and void

using Medium Density Fireboard (MDF) trimmings