these handboards are 3D-printed from plastic waste and discarded prototypes

from prototypes to handboards

over fourteen million tons of plastic have infested the sea, harming the marine species and contaminating the water. while brands and businesses have sworn to forge products that will alleviate the damage of plastic in the water bodies, not everyone has put forward their commitment to manufacturing these green, tangible products. if they need a nudge or a source of inspiration, they can turn to lautaro lucero and tadeo lucero, the designers behind the multidisciplinary uido design studio who just introduced ‘wabo waterboards’, a series of handboards crafted out of plastic and using 3D prototyping.

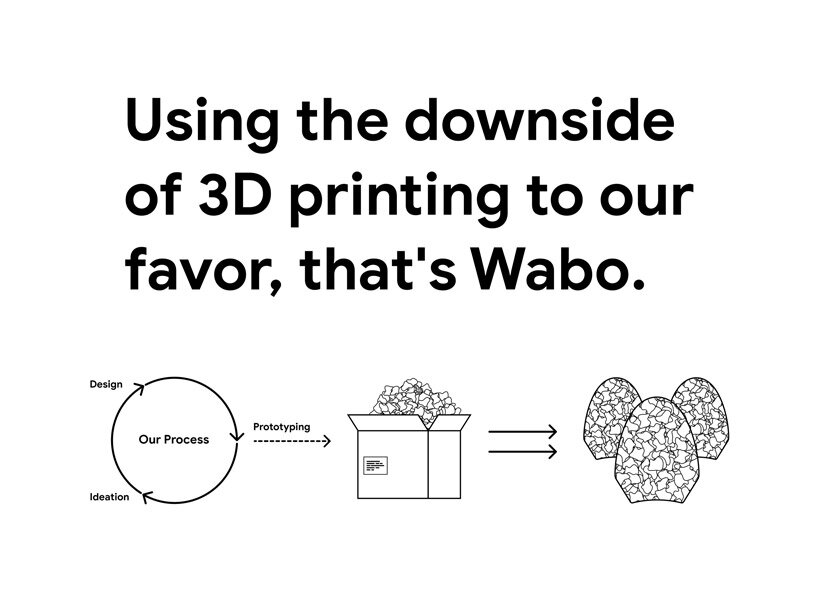

‘at uido, each time we do a product design project, it is an essential part of the process to make 3d printed prototypes. so, throughout the year, we fill tons of boxes with those prototypes of different colors and sizes,’ says designer lautaro. ‘our commitment to the planet is serious, and our only waste as a company is those prototypes, so we started thinking about what we can do with them and how we can transform them into a new and fun product. that is how the idea of making handboards for surfing waves was born.’

images courtesy of uido design studio

design process

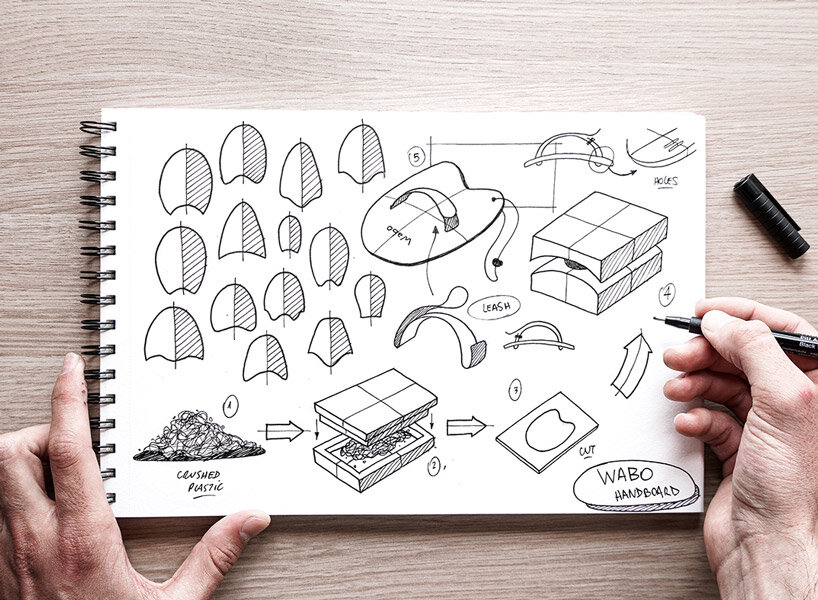

based on the blueprint the duo drafted, the design of the handboards had undergone reiterations before they settled with a fin-like look. as for the materials, they decided to shred the plastic and make 6mm plates to cut. they pressed the bits of plastic into a mold and cropped out the excess before attaching the elastic leash on top. the duo hopes to make ride-waving fun and vibrant by using zest-colored plastic. as they put it, one man’s trash is another man’s handboard.

these handboards are 3D-printed from plastic waste and discarded prototypes

from handboards to coffee cork grips

the multidisciplinary design studio believes in bringing design-based solutions to all kinds of projects. for instance, the team has produced cups made of ceramic and using a production technique called ‘slip casting.’ the cup’s removable cork grip prevents hand contact with the hot ceramic surface when users take a sip of their coffee. another design they gave birth to pointed towards ‘buba lamp,’ a desk lamp from the boolean union of a sphere and a cone, resulting in a simple and sophisticated product whose head seems to nod to the users as it emits light.

these handboards make ride-waving more fun and green

the sketch or draft of the handboards

commitment of the brand

the plastic waste the designers used

orange-colored handboard