these 3D printed soil structures could become the building blocks of future homes

university of virginia launches ‘bioconstruction’ project

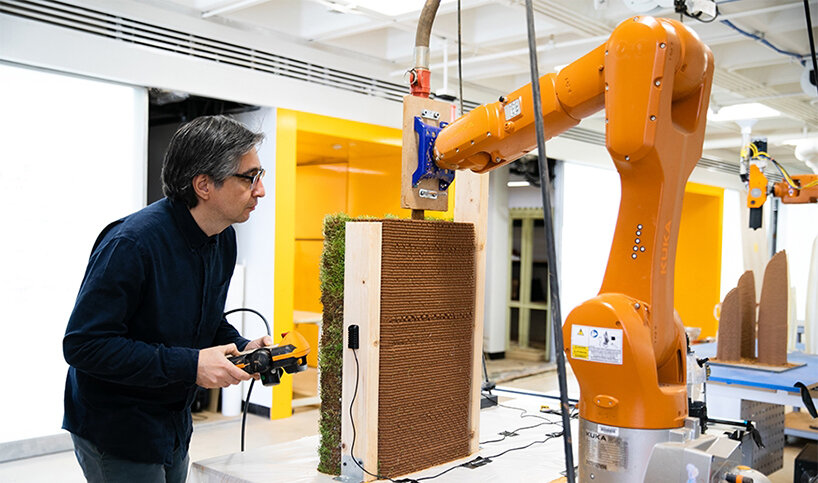

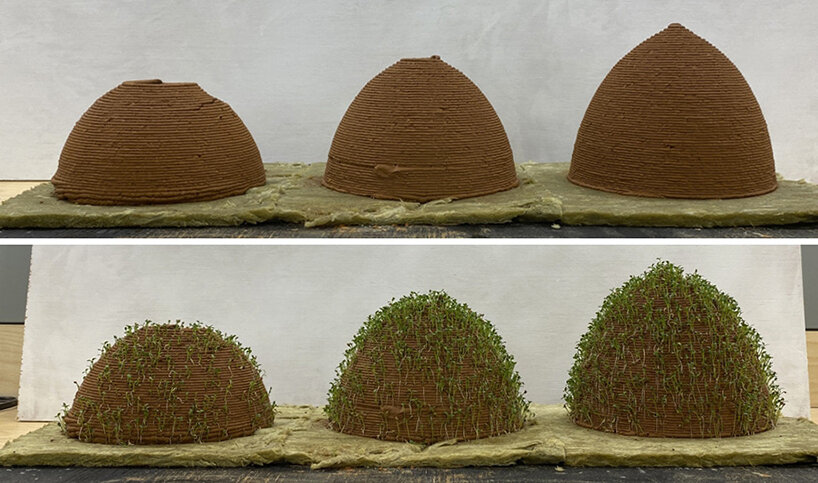

A team of researchers at the University of Virginia has developed a unique bioconstruction technology that could change how future buildings will be built. Published in the peer-reviewed journal ‘Additive Manufacturing,’ the project focused on physically merging nature and architecture as a step toward more sustainable building practices: the result is a series of 3D-printed and geometrically complex flowering structures made of soil and seeds. Expanded at a larger scale, these volumes could very well become the building blocks of future homes.

To carry out the experiment, Ji Ma, assistant professor at UVA’s School of Engineering and Applied Science, joined forces with two other university members — research professor David Carr at the Department of Environmental Sciences and assistant professor Ehsan Baharlou at the School of Architecture — and his student Spencer Barnes.

The research team joined the exploding trend of 3D printing, a technology responding to the growing global need for more affordable housing, green building practices, and a circular economy.

all images © Tom Daly via University of Virginia

exploring circular additive manufacturing

‘We moved to soil-based ‘inks’ to derive additional benefits from circular additive manufacturing,’ explains Ehsan Baharlou. ‘We are working with local soils and plants mixed with water; the only electricity we need is to move the material and run a pump during printing. If we don’t need a printed piece or if it isn’t the right quality, we can recycle and re-use the material in the next batch of inks.’

After several testing rounds on the soil mixture, the structures were able to grow plants, but not just any. ‘3D-printed soil tends to lose water more quickly and keeps a stronger grip on the water it has,’ Ji Ma states ‘Because 3D printing makes the environment around the plant drier, we have to incorporate plants that like drier climates. The reason we think this is the case is because the soil gets compacted. When the soil is squeezed through the nozzle, air bubbles are pushed out. When the soil loses air bubbles, it holds onto water more tightly.’

3D-printed soil structures successfully growing plants

Ultimately, the goal is to encourage practices that reduce the carbon footprint of a building by resorting to locally sourced bio-materials. This means, moving away from conventional resources that are unrecyclable, non-reusable, and unadaptable. Bio-construction, therefore, opens the door to low-cost, low-energy, and climate-friendly alternatives in the world of architecture and engineering.

Ehsan Baharlou, Assistant Professor at UVA’s School of Architecture

project info:

name: Bioconstruction – 3D-printed soil structures

research team: Ji Ma, Ehsan Baharlou, David Carr, Spencer Barnes

institution: University of Virginia (UVA)