Osaka Expo 2025 Japan Pavilion / Nikken Sekkei

Courtesy of Ministry of Economy, Trade and Industry

Courtesy of Ministry of Economy, Trade and Industry

+ 23

+ 23

Area

Area of this architecture project

Area:

11000 m²

Year

Completion year of this architecture project

Year:

2025

Lead Architect:

Nikken Sekkei Ltd

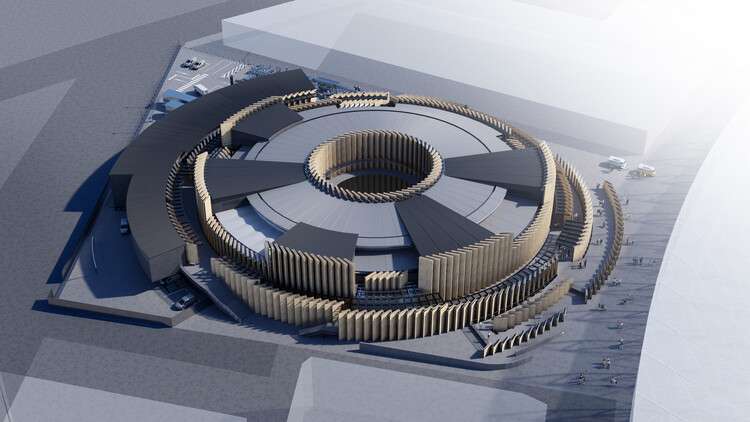

Exterior image. Image Courtesy of Ministry of Economy, Trade and Industry

Exterior image. Image Courtesy of Ministry of Economy, Trade and Industry

Text description provided by the architects. The Japan Pavilion at Expo 2025 Osaka, Kansai, serves as the official pavilion of the Japanese government. Designed in response to its exhibition concept “Between Lives,” the architecture embodies themes of “the relay of life” and “the cycle of life” through a repetitive, staggered arrangement of cross-laminated timber (CLT) panels in a concentric circular formation.

Exterior image. Image Courtesy of Ministry of Economy, Trade and Industry

Exterior image. Image Courtesy of Ministry of Economy, Trade and Industry

A Pavilion Like a Forest – The use of wood, whether as a tree or timber, symbolizes the cycle of life and the circular economy. Among various timber technologies, CLT offers a novel system that enhances the potential of wood utilization by transforming small-diameter logs into thin laminates, which are stacked to create large panels. Additionally, a proportion of the CLT panels used in this pavilion will be disassembled and returned to their lender, the Japan Cross Laminated Timber Association, after the exhibition, where they are to be repurposed and used in subsequent architectural projects. This regenerative characteristic of the architecture serves as a testament to its alignment with the pavilion’s overarching theme of “cycle.” The gaps between the CLT panels facilitate visual permeability, thereby establishing a seamless connection between exterior and interior environments, as well as the exhibition and the architecture. This interplay introduces an additional layer of “in-betweenness,” expanding the notion of the cycle.

Concept image. Image Courtesy of Ministry of Economy, Trade and Industry

Concept image. Image Courtesy of Ministry of Economy, Trade and Industry

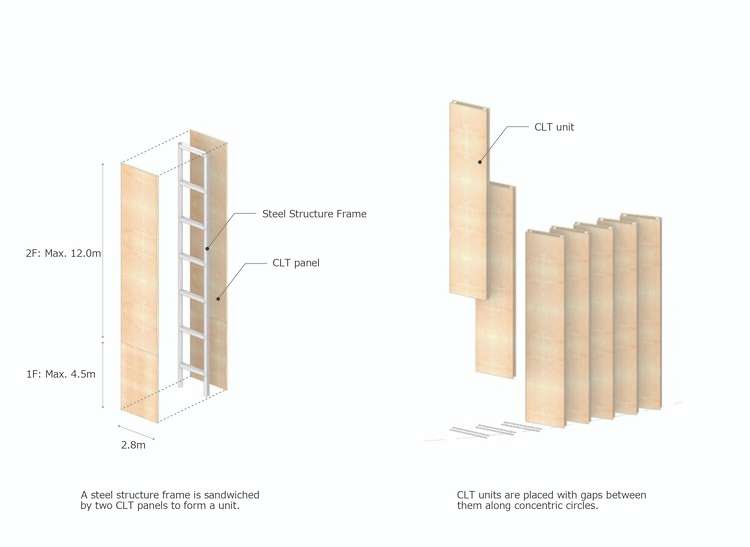

A Wooden Structure that Can Withstand the Elements: Exterior CLT Clad Framing System – The construction of the building’s circular form is achieved through the radial arrangement of CLT panels measuring up to approximately 3m × 12m in a staggered formation along the circumference. The building’s circular form is therefore achieved with rectangular panels. Maximum-sized domestic CLT panels are utilized, maintaining an upright position with a simple configuration. A steel frame is employed and sandwiched by two CLT panels, expressing and showcasing CLT as the key architectural element both internally and externally.

CLT units arranged along the building perimeter. Image Courtesy of Ministry of Economy, Trade and Industry

CLT units arranged along the building perimeter. Image Courtesy of Ministry of Economy, Trade and Industry

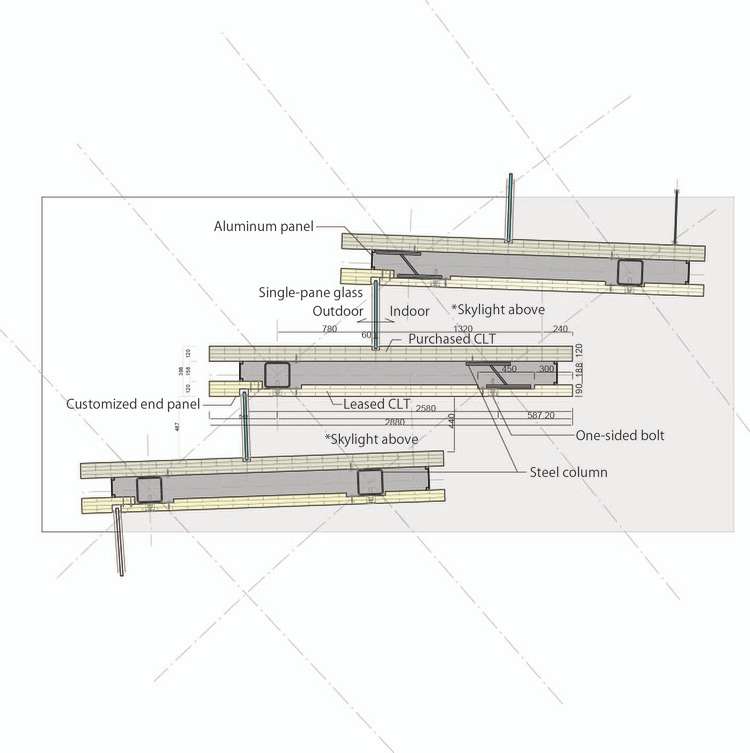

A Reusable Approach to CLT – The CLT panels utilized in this project are designed to be disassembled, returned to their lender, and repurposed after the exhibition. To facilitate the reuse of the panels, panel fabrications were designed to minimize slits, routing, and drilled openings. No adhesives were used, ensuring ease of disassembly and reassembly. Instead, a dry method of joining secures the CLT panels to the steel framework. Structural screws and blind bolts were employed to ensure precise, gap-free joints, even within confined areas. Structural testing was conducted to verify the strength and rigidity of the joints, as well as to assess the ease of construction and disassembly using test mock-ups. The CLT panels are configured with 3-ply (3 layers) for the interior and, adding an extra ply for protection, with 4-ply (4 layers) for the exterior. Slits are fabricated in the protection ply to allow for the direct insertion of glass, creating a straightforward yet expressive façade that highlights the presence of the CLT panels. In total, approximately 1,600 cubic meters of CLT is used.

View of the completed exterior. Image Courtesy of Ministry of Economy, Trade and Industry

View of the completed exterior. Image Courtesy of Ministry of Economy, Trade and Industry

A Circular Structural System – To achieve both a highly flexible exhibition space and a structure that highlights the architectural expression of CLT, the pavilion employs steel for its core structural system. Exposed CLT components serve as seismic-resisting elements, showcasing a clearly defined composition. The structure consists of evenly spaced steel structural frames arranged radially using small and mid-size steel sections. In the circumferential direction, each frame is connected solely by secondary beams, creating a simple yet rational system that shapes the circular plan. For well-balanced seismic stability, CLT structural walls are strategically positioned along the outer, middle, and inner rings of the plan. These walls are meticulously arranged in a staggered formation, alternating their orientation in each concentric zone. This configuration addresses a critical structural challenge unique to this building, wherein discontinuities in the floor plates (horizontal structural surface elements) occur due to the exhibition layout. Concurrently, it ensures adequate torsional rigidity throughout each zone of the circular plan. These CLT structural walls fulfill several functions: 1) delineating the spatial divisions within the exhibition space, 2) forming both the interior and exterior walls of the building, and 3) functioning as seismic-resistant elements. The aim of integrating the exhibition design, architectural design, and structural performance into a unified system has been achieved.

Courtesy of Ministry of Economy, Trade and Industry

Courtesy of Ministry of Economy, Trade and Industry

Detailing Deliberately Made to Look Simple: Structural CLT Direct-Glazing Curtain Wall – This glass curtain wall (GCW) incorporates two key structural innovations. The first innovation pertains to the glass’s accommodation of deformation caused by wind pressure on the CLT panel. The wall unit that serves as the glass frame in this case has a somewhat complex deformation, and by precisely drawing and verifying how the glass slides and rocks to accommodate this complex deformation, it has been confirmed that deformation tracking is possible. Additionally, as CLT naturally undergoes warping and shrinkage due to its material property, finite element method (FEM) analysis was performed to assess stress concentrations of the glass where it is in contact with the CLT panel. The second innovation is the direct glazing of glass onto the CLT wall units without any metal framing. Given the lack of precedent regarding the compatibility between sealant and wood, adhesion and contamination resistance tests were conducted in advance to confirm feasibility. This GCW not only expands the possibilities of integrating wood and glass but also offers a solution to the question of what the ideal exterior material of a temporary structure should be, contributing to a construction process with fewer components and reduced costs.

Curtain wall composed of CLT units. Image Courtesy of Ministry of Economy, Trade and Industry

Curtain wall composed of CLT units. Image Courtesy of Ministry of Economy, Trade and Industry Courtesy of Ministry of Economy, Trade and Industry

Courtesy of Ministry of Economy, Trade and Industry Courtesy of Ministry of Economy, Trade and Industry

Courtesy of Ministry of Economy, Trade and Industry

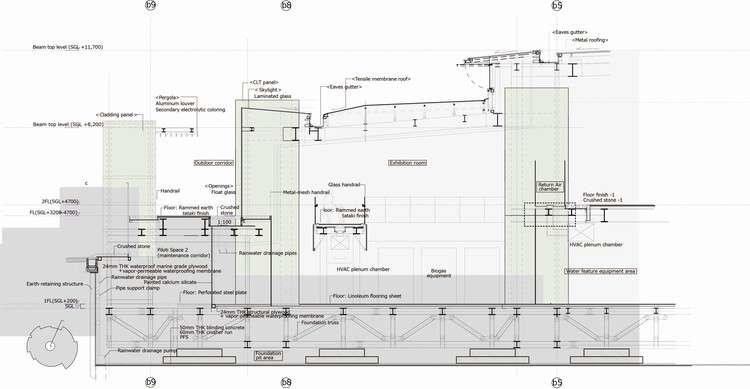

The Integration of Exhibition and Architecture – At past Expos, pavilions were often designed as independent white cubes, with little to no integration between the exhibition and the architectural design. This project, however, sought a seamless integration of exhibition planning and architectural design, developing both in parallel. To complement the exhibition content, the pavilion creates a variety of “exhibiting environments”: including a bright, open atrium that allows natural light to filter through the membrane roof, a softly illuminated space with skylights that accentuate the texture of CLT surfaces, a darkened room with a low ceiling that encourages visitors to focus on the displays and an iconic outdoor space centered around a water feature. The provision of diverse exhibiting settings—including indoor and outdoor, light and shadow, and spatially large and small—the pavilion invites visitors to experience the exhibition narrative with all their five senses. To ensure this integration, the architectural design team was tasked with the coordination of the exhibition planning, leading the entire Japan Pavilion project. During the detailed design phase, a fully BIM-integrated process enabled real-time visual communication not only among architects but also with the exhibition designers, construction teams, and other stakeholders, streamlining the entire design process.

Courtesy of Ministry of Economy, Trade and Industry

Courtesy of Ministry of Economy, Trade and Industry Courtesy of Ministry of Economy, Trade and Industry

Courtesy of Ministry of Economy, Trade and Industry Courtesy of Ministry of Economy, Trade and Industry

Courtesy of Ministry of Economy, Trade and Industry

A Pavilion That Eats Trash – As a symbolic expression of “the Cycle of Life” theme, the pavilion is equipped with a biogas plant. Food waste collected from the Expo grounds is deformed by microbial fermentation, generating biogas that is converted to electricity for the pavilion. The exhibition spaces are located on the second floor, while the first floor houses the plant and utility areas. This sectional arrangement ensures a clear delineation of functions while enabling visitors to observe the biogas facility in operation through an open atrium, thereby integrating the biogas plant into the exhibition experience.

Biogas plant implemented in the Japan Pavilion. Image Courtesy of Ministry of Economy, Trade and Industry

Biogas plant implemented in the Japan Pavilion. Image Courtesy of Ministry of Economy, Trade and Industry

A Dynamic Exhibition Space for a Shared Experience for All – A gently sloping outdoor corridor encircles the second-floor exhibition, ensuring individuals with disabilities have barrier-free access and a route. This universal design approach ensures equal participation and shared experiences for all. The outdoor corridor functions as an access route to three exhibition areas and as an emergency route, designed to safely evacuate individuals with disabilities. To enhance the pavilion’s accessibility, workshops were conducted with experts from various fields, and their feedback was incorporated into the planning, including considerations such as slope gradients, material textures, and color contrasts.

Courtesy of Ministry of Economy, Trade and Industry

Courtesy of Ministry of Economy, Trade and Industry

A Comfortable Outdoor Corridor Shaped by Natural Forces – The corridor is covered by a pergola, forming a sheltered space where glimpses of the interior exhibition rooms and the surrounding landscape can be seen through the gaps between vertical timber panels. The open design allows sea breezes to penetrate the building, creating an engawa-like space that subtly blurs the boundary between inside and outside. Within the exhibition space, the spatial composition resembles a natural terrain, with several floors arranged across multiple levels. A series of atriums and sloped walkways create a dynamic, three-dimensional experience, allowing visitors to engage with the exhibition from a variety of viewpoints.

Outdoor corridor image . Image Courtesy of Ministry of Economy, Trade and Industry

Outdoor corridor image . Image Courtesy of Ministry of Economy, Trade and Industry

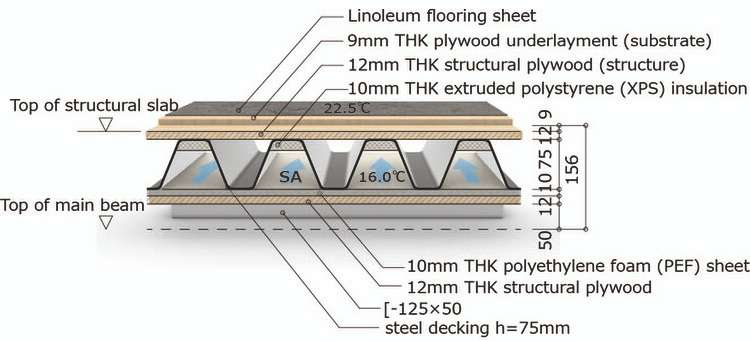

Challenges Based on the Time Limitations of a Temporary Structure – The design of the pavilion, given its temporary nature, exposes the CLT panels on both the exterior and interior, creating a distinctive architectural expression. Addressing structural integrity and weather resistance measures, the basic configuration of the CLT panels was a 3-ply (three layers) for the interior panel and a 4-ply (3 layers) for the exterior. To mitigate the low bearing capacity of the reclaimed ground, floors of the exhibition spaces employ a dry composite floor system, combining structural plywood and corrugated floor decking with screws. This system improves walking comfort while enabling floor installation in the early stage of construction. To facilitate disassembly after the exhibition, the floor decking sheets are affixed to the steel beams using tapping or drilling screws, eliminating the need for welding and ensuring a fully dry construction. Full-scale testing was conducted to verify walking comfort and vibration performance. Additionally, the floor system was designed to integrate the building’s mechanical design. Cold air is distributed through the space between the floor decking and plywood, enhancing air conditioning efficiency. This integrated floor system is primarily adopted in the exhibition areas, covering approximately 70% of the total floor area and significantly reducing the use of concrete.

A dry-construction air duct utilizing floor decking. Image Courtesy of Ministry of Economy, Trade and Industry

A dry-construction air duct utilizing floor decking. Image Courtesy of Ministry of Economy, Trade and Industry Detailed section. Image Courtesy of Ministry of Economy, Trade and Industry

Detailed section. Image Courtesy of Ministry of Economy, Trade and Industry

A Foundation Designed to Flexibly Handle Ground Subsidence (Foundation Truss + Spoil Removal Balance) – The site’s location on a substantial reclaimed land area necessitated the implementation of structural measures to address the consolidation settlement of the underlying clay layer. To address this issue, the foundation adopts a spread footing (floating foundation system), excavating approximately 2.5 meters below ground level to balance the weight of the spoil removal with the load of the building. To mitigate concentrated settlement caused by uneven axial loads on the columns, a rigid steel-truss beam system was introduced. This foundation structure effectively distributes the axial loads of columns to the ground, minimizing differences in settlement depth and ensuring overall stability. Furthermore, due to differences in reclamation periods between the eastern and western sections of the site, there was a concern about significant differences in settlement depth. To accommodate potential differential settlements, spaces for jacking were prepared in the foundation, allowing for level adjustments during construction when necessary. Construction proceeded concurrently with the measurement of subsidence, the establishment of threshold values for jack-up adjustments, and the execution of pre-simulation analyses.

Concentric formation of the foundation truss under construction (site photo). Image Courtesy of Ministry of Economy, Trade and Industry

Concentric formation of the foundation truss under construction (site photo). Image Courtesy of Ministry of Economy, Trade and Industry

A Pavilion Showcasing the Back of the House – The architectural design of the pavilion reflects the theme of Expo 2025, “Designing Future Society for Our Lives”, which embodies the idea that everything exists through interconnected relationships and is supported by others. This concept is expressed in the building structure, with the steel frame, CLT panels, and glass forming a mutually supportive design. The steel frame supports the CLT panels, while the CLT panels stabilize the steel frame against horizontal loads. The CLT panels support the glass, while the glass mitigates the deformation of the CLT panels caused by wind pressure. By reducing decorative elements as much as possible, the design itself emerges from this interdependent structural composition. At the same time, conventionally hidden elements, which accommodate all the utilities that sustain a building, including the plant, are visually exposed.

Courtesy of Ministry of Economy, Trade and Industry

Courtesy of Ministry of Economy, Trade and Industry

By engaging with these structural and environmental elements, which are often overlooked, along with the scent of wood, the subtle shifts in temperature, and the changing qualities of natural light, the pavilion offers a sensory experience that fosters genuine connections within the space, leaving a lasting impression on one’s memory. This direct, spatial encounter contrasts with the superficial virtual environment, offering an exhibition space that lives up to the aspirations of the theme for this Expo.

Bird’s-eye view . Image Courtesy of Ministry of Economy, Trade and Industry

Bird’s-eye view . Image Courtesy of Ministry of Economy, Trade and Industry Cross section. Image Courtesy of Ministry of Economy, Trade and Industry

Cross section. Image Courtesy of Ministry of Economy, Trade and Industry Courtesy of Ministry of Economy, Trade and Industry

Courtesy of Ministry of Economy, Trade and Industry Courtesy of Ministry of Economy, Trade and Industry

Courtesy of Ministry of Economy, Trade and Industry