MIT engineers use discarded tree forks to build wooden structures

USING DISCARDED TREE FORKS AS LOAD-BEARING JOINTS

Knowing that Portland cement accounts for 36% of all emissions related to construction activities and 8% of total anthropogenic CO2 emissions, MIT engineers are taking to nature to study its structures and translate them into wooden buildings. The idea is to allow architects to use discarded tree forks as load-bearing joints.

Concerned with climate change, researchers, engineers and architects are looking into the timber industry to find wooden replacements for traditional concrete and steel elements.

‘THE GREATEST VALUE YOU CAN GIVE TO A MATERIAL IS TO GIVE IT A LOAD-BEARING ROLE IN A STRUCTURE’ – MUELLER

Usually, the timber industry is more interested in harvesting the straight sections of trees and disregarding the knots and forks, which are usually turned into pellets and burned. Observing those trends, Caitlin Mueller, an associate professor of architecture and of civil and environmental engineering in the Building Technology Program at MIT, has been looking with her Digital Structures team how to upcycle these pieces by using them in construction as structural components.

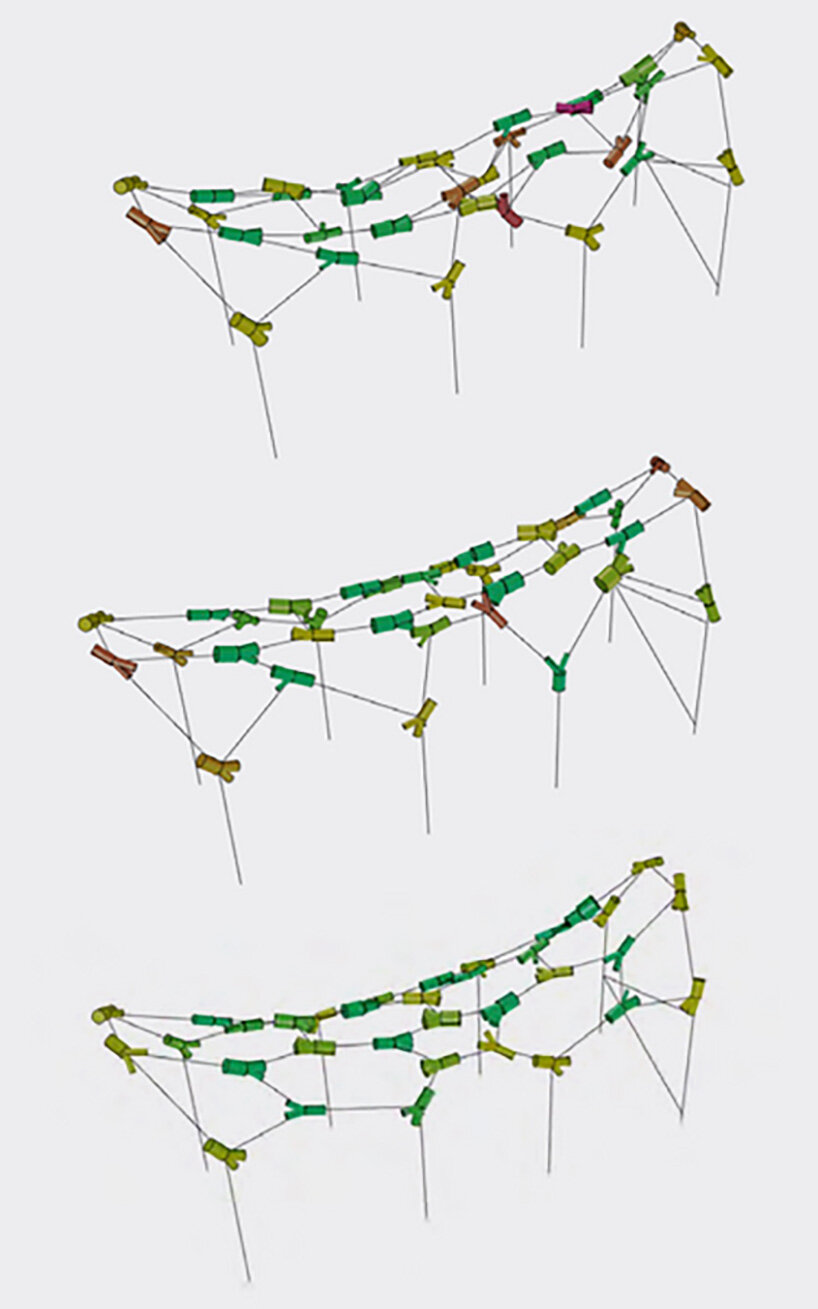

‘The greatest value you can give to a material is to give it a load-bearing role in a structure,’ Mueller, who has been focusing with her team on tree forks, said. The Y-shaped natural pieces are the perfect replacement for similar Y-shaped nodes where straight elements come together in architectural drawings.

‘Tree forks are naturally engineered structural connections that work as cantilevers in trees, which means that they have the potential to transfer force very efficiently thanks to their internal fiber structure,’ Mueller continued. ‘If you take a tree fork and slice it down the middle, you see an unbelievable network of fibers that are intertwining to create these often three-dimensional load transfer points in a tree. We’re starting to do the same thing using 3D printing, but we’re nowhere near what nature does in terms of complex fiber orientation and geometry.’

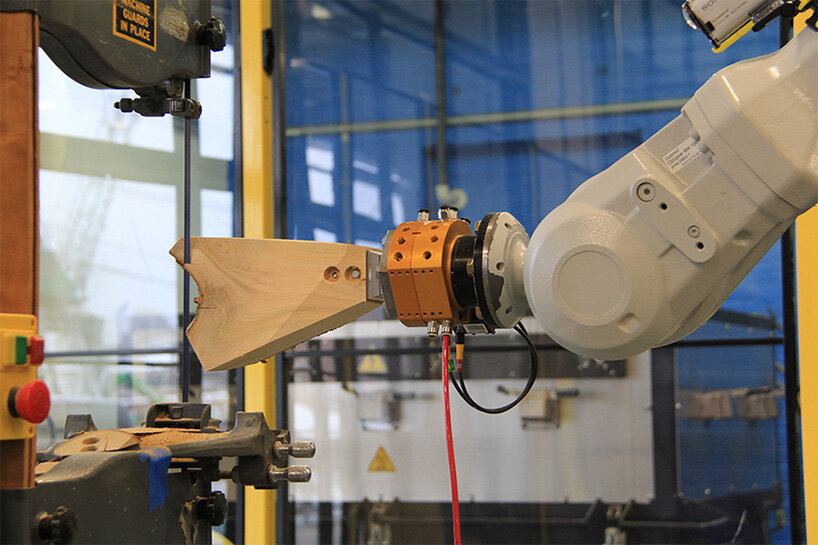

Mueller and her team developed a workflow that uses the natural structures together with digital tools. By using computational tools, the team made it possible to use the tree forks in structural roles, as it doesn’t need lots of cutting, which is costly.

Mueller believes the research is ‘at least potentially scalable and potentially achievable within our industrialized materials processing systems.’

See more here.

juliana neira I designboom

may 07, 2022