INDEXLAB + GIMAC 3D print custom bike frame using robotic manufacturing

the new01bike frame: a path to mass-customization

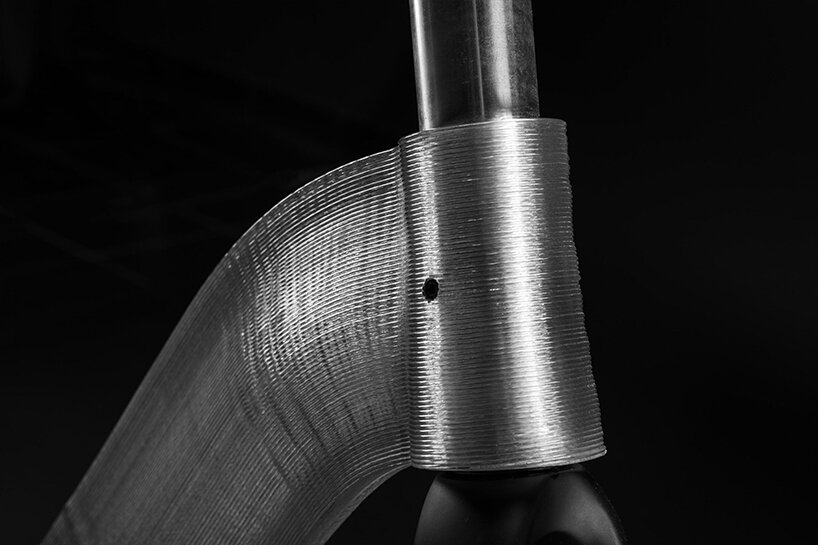

On the occasion of Milan Design Week 2022 at Palazzo Bandello, INDEXLAB and GIMAC-EXGINEERING have unveiled New01bike, a 3D-printed frame for custom bicycles. The bike frame is the first of its kind, made of 100% recycled polycarbonate through the process of conformal RAM (Robotic Additive Molding).

‘Custom ergonomic bikes are not only costly and slow to manufacture but also very difficult to mass-produce since they are tailored for particular needs and usages. On the other hand, mass-serialized bikes are seldom so versatile that they accommodate different user body proportions and measures, as they are made for the ‘standard user’. New01bike was created to fill this gap, make a custom bike affordable, fast, and easy to mass-produce and recycle,’ explains Pierpaolo Ruttico, founder of INDEXLAB.

merging rapid prototyping with data-driven processes

Designed by Francisco Martins Carabetta of INDEXLAB (see more here), a leading design and innovation research lab in Italy, New01bike was developed in cooperation with GIMAC – eXgineering (see more here), a leader in plastics microextrusions and robotic additive molding (RAM). Employing technologies that involve robotic manufacturing and computational design processes, the first working prototype took about eight hours to manufacture, from printing and milling to assembling.

Adopting additive manufacturing techniques leads to an essentially transparent frame – weighing about eight kilograms – crafted out of what once could have been safety glasses, CDs, and DVDs. The final shape of the New01bike is, therefore, a direct consequence of the whole manufacturing process, developed in conjunction with Federico Bordoni, a research fellow at INDEXLAB and algorithmic developer of the project.

‘It is precisely this dedicated algorithm that, through parametrization, further enables the scaling of the project to produce a holistic ‘design for all’ product, allowing control of every detail, movement, and aspect of the 3D printing and milling processes, to tailor the bike to every possible user; in other words, to skew off from mass serialization and embrace mass customization,’ continues Ruttico.

The growth of what is called Industry 4.0, which merges rapid prototyping with data-driven processes, helps create custom bike frames without needing a new mold for each bike, therefore optimizing production by saving time and cost. In this case, two six-axis robots were used, one for 3D printing and the other for milling out of the frame the necessary attachments for the bottom bracket and the rear wheel, and cutting the support parts.

3D printing was executed using conformal RAM (robotic additive molding). In other words, the team molded the New01bike frame on top of a 3D surface/object to carve out a unique curved line profile and ensure better sheer strength than that provided by a three-axis machine.

‘The objective will be to create a local circular system of recycling and manufacturing, achieving an organized approach that promotes sustainable materials and new production methods to build products without sacrificing functionality,‘ concludes INDEXLAB.

Robotic Additive Molding by GIMAC- EXGINEERING