How are New Construction Materials Prioritizing Human Safety and Wellbeing?

How are New Construction Materials Prioritizing Human Safety and Wellbeing?

It is expected that by 2050, the rapid depletion of raw materials will leave the world without enough sand and steel to build concrete. On the other hand, the cost of building continues to soar, with an increase between 5% and 11% from last year. And with respect to its impact on the environment, the construction industry still accounts for 23% of air pollution, 50% of the climatic change, 40% of drinking water pollution, and 50% of landfill wastes. Evidently, the construction industry, the environment, and the human race are facing several challenges that are influenced by one another, but it is the human being who is at the greatest disadvantage.

As a response to global challenges such as climate change, discrimination, and physical vulnerability, designers and engineers from across the world have developed innovative construction materials that put the human wellbeing first in urban, architecture, and interior projects.

It comes as no surprise that design has become an essential contributor to the scientific processes of material development. Since the beginning of mankind, materials have been shaping humanity, bringing about tools that have advanced the social, economic, and civil structures of the human race. Fast-forward to modern times and evolving needs, innovative designs, along with cutting-edge materials and technologies are shaping industries, economies, and ultimately, the future. The past decade, however, saw an unprecedented focus on human wellbeing, whether it being physical, emotional, or mental, which became a starting point for the development of new materials.

Light-emitting cement / concrete has been one of the most comprehensive construction materials within the past decade. Along with its ability to illuminate highways, roads, and bicycle lanes at night without using electricity, ensuring pedestrian safety, the innovative material can also offset the material’s poor environmental performance. Recently, undergraduate engineering students at the American University in Cairo have developed a bioluminescent-like, sunlight-absorbing concrete, which emits its energy at night as light rays “to reduce the massive amount of energy used in lighting highways and street signage needed for safe rides”. Glow-in-the-dark concrete has long been considered as a significant solution for the construction industry’s impact on the climate crisis. Initially developed by Dr. Jose Carlos Rubio from the Michoacan University of Saint Nicholas of Hidalgo in Mexico, the innovation modifies the microstructure of cement to eliminate the crystals so that once it’s combined with water, it changes into a gel form, absorbs solar energy, and releases it in the form of light.

Although each material has its own lifespan, most construction materials, especially composites, tend to deteriorate after several years of load-bearing and exposure to external factors. Materials often show this deterioration, such as through cracks, but in certain cases, damages tend to be undetected, creating a physical risk for people continuously using these surfaces. Tackling this dilemma, ETH Zurich researchers in collaboration with researchers from the University of Fribourg have developed a new type of laminate that changes color as soon as the material is deformed. With an aim to develop new techniques for the early detection of damage or possible failure of certain materials, the lightweight composite laminate is composed of alternating layers of a plastic polymer and artificial mother-of-pearl. The mother-of-pearl is exclusively developed by the Complex Materials Laboratory, and is modeled on the mussel shell, with several glass platelets compacted and arranged in parallel, making it extremely hard and break-resistant. The second layer consists of a polymer with an additional indicator molecule. This molecule is activated as soon as the polymer experiences stretching forces by changing its fluorescence. The more the material stretches, the more of these molecules are activated, leading to a more intense fluorescence.

As a country heavily prone to earthquakes, Japan has recently begun using CABKOMA strand rods on the exteriors of its buildings. As seen in Kengo Kuma’s Komatsu Seiren’s Head Office, this thermoplastic carbon fiber composite is used specifically for resiliency purposes by protecting the structures from earthquakes. Along with its aesthetic features, it is the lightest seismic reinforcement in the world with high tensile strength.

To detect when users are riding on the sidewalk, micro-mobility company Lime has built its own camera-based sidewalk detection technology. Although the project will be up to the cities to choose whether to audibly alert the riders, actually slow them down, or both, both functions are available. Cities have long been blaming micro-mobility companies and scooter riders for sidewalk riding, but rarely took the initiative to invest in properly-protected bike lanes. This has caused several major operators to implement some form of scooter advanced rider assistance system (ARAS) over the past years.

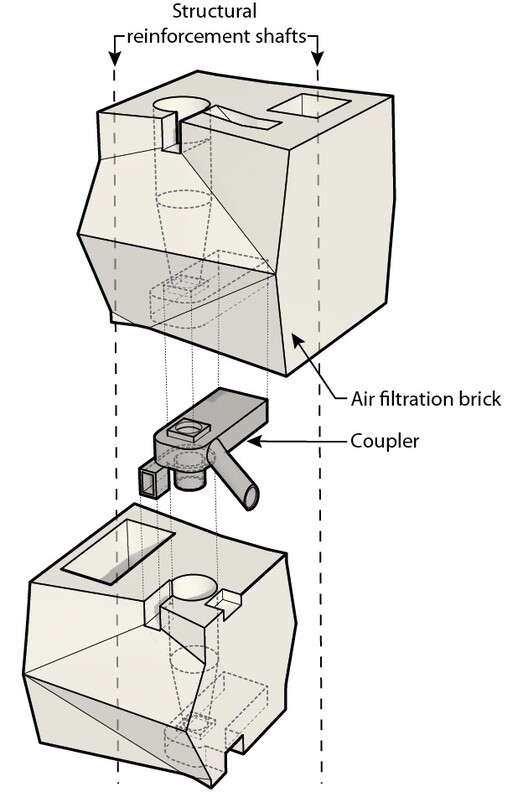

As a response to the current climate crisis, especially seeing that the construction industry contributes to 23% of air pollution, architects and designers have taken great measures to reduce carbon footprint during and after construction. “Breathe Bricks”, or pollution absorbing bricks, are an effective alternative to conventional bricks, developed by Ar. Carmen Trudell, an assistant professor at Cal Poly San Luis Obispo’s School of Architecture. Inspired by ‘cyclone filtration’ in vacuum cleaners, these bricks follow the principle of air filtration by filtering the outside air, separating the pollutants and dust, then transferring it to the interior of the structure. The bricks are shaped as a porous concrete block with interior shafts and a faceted design to direct the airflow inside the unit.

After the pandemic, almost every industry launched its own “antibacterial” product, and the interior design industry was no exception. Several paint companies developed interior paints for walls and furniture surfaces with patented sanitizing technologies that are claimed to kill 99 percent of certain bacteria (staph, E. coli, MRSA and VRE, to name a few) that land on its surface within a couple of hours of exposure. In fact, the antimicrobial paints and coatings market size is expected to grow from USD 3.7 Billion in 2020 to USD 9.54 Billion by 2029, indicating its positive impact on users.

This article is part of the ArchDaily Topics: The Future of Construction Materials. Every month we explore a topic in-depth through articles, interviews, news, and projects. Learn more about our ArchDaily topics. As always, at ArchDaily we welcome the contributions of our readers; if you want to submit an article or project, contact us.