cookfox and buro happold team up to design bird and bee-friendly terracotta façade

cookfox & buro happold design biophilic terracotta façade

During the Architecture Ceramic Assemblies Workshop (ACAW) hosted by Boston Valley Terra Cotta, COOKFOX Architects teamed up with façade engineers from Buro Happold to explore ceramics as a high-performance biophilic façade. The team was inspired to push the boundaries of architectural terracotta by creating a screen wall that can incorporate microhabitats for bees, plants, and birds. The result sees a standardized stacking module that filters sunlight and provides the framework for a customizable series of terracotta units.

the screen incorporates a customizable series of terracotta units capable to shelter birds, bees and plants

image courtesy of Architecture Ceramic Assemblies Workshop (ACAW) | head image courtesy of COOKFOX Architects

modular screens shelters birds, bees and plants

The Boston Valley Terra Cotta Workshop is a hands-on research and development program that brings together design professionals to explore novel design ideas for architectural terra cotta. Through months of design, experimentation, and fabrication, the architects from Cookfox and engineers from Buro Happold created a modular structure composed of customizable terracotta pods that provide shelter for different species.

One pod houses tubes in different sizes and materials where dozens of native solitary bees can nest. A second type of pod serves as a planter collecting rainwater from the façade and storing excess water in its lower section for later irrigation use. A third pod creates optimal shelter and habitat for native birds. The façade promotes and educates on the various native ecosystems that survive in our urban environments.

The bigger base modules into which the micro-habitat pots are fitted are made of a high-fired and high-grogged ceramic that is slip-cast or press-molded for large-scale, cost-effective production. This clay body is designed to withstand freeze-thaw cycles, shrinkage during manufacturing, and the rigors of façade applications. The slip-cast, low-fired clay body of the micro-habitat pods provides for water permeability to sustain each pod’s program.

a second pod serves as a planter collecting rainwater from the façade and storing excess water for later irrigation use

image courtesy of COOKFOX Architects

During the design process, the team collaborated with fabricators to create unique glazes and coloured clays known as ‘engobe.’ The team was able to explore the many qualities of color, opacity, and sheens, as well as how a glaze can pool in valleys or ‘break’ over peaks, and how glaze interacts with engobe, thanks to this progressive experimentation. The procedure also examined the advantages and disadvantages of high-volume industrial production.

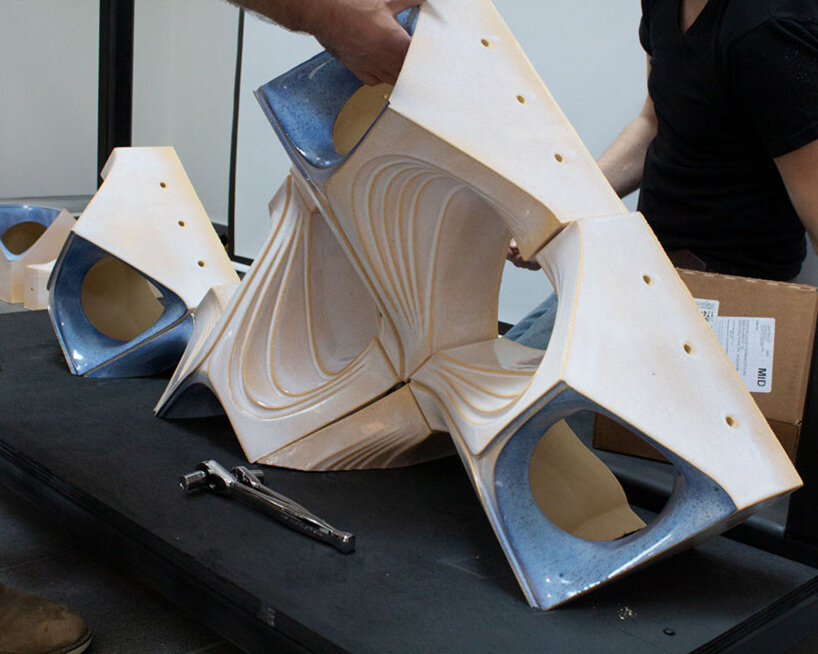

COOKFOX and Buro Happold began working together in December 2020 and met virtually throughout the winter to develop the concept. The ceramic pods and modules were made in Kansas City, Missouri, then sent to the Boston Valley facility in Buffalo, New York. The team met in Buffalo in mid-August to assemble the full-scale model of the screen wall and components.

one pod houses tubes in different sizes and materials where dozens of native solitary bees can nest

image courtesy of COOKFOX Architects

the team met in mid-August to assemble the full-scale model of the screen wall and components

image courtesy of Architecture Ceramic Assemblies Workshop (ACAW)

exploring ceramics as a high-performance biophilic façade

image courtesy of Architecture Ceramic Assemblies Workshop (ACAW)

image courtesy of COOKFOX Architects

image courtesy of COOKFOX Architects

image courtesy of COOKFOX Architects

project info:

name: Bird and Bee Friendly Façade

designers: COOKFOX Architects ( Spencer Lapp, AIA, Associate and Zach Grzybowski), Buro Happold (Andre Parnther, Associate and Spring Wu, LEED AP, Façade Engineer)

workshop: Architecture Ceramic Assemblies Workshop (ACAW)

myrto katsikopoulou I designboom

sep 22, 2022