aluminum ‘digital house’ demonstrates plug-in construction in german forest

german architects explore digital build strategies

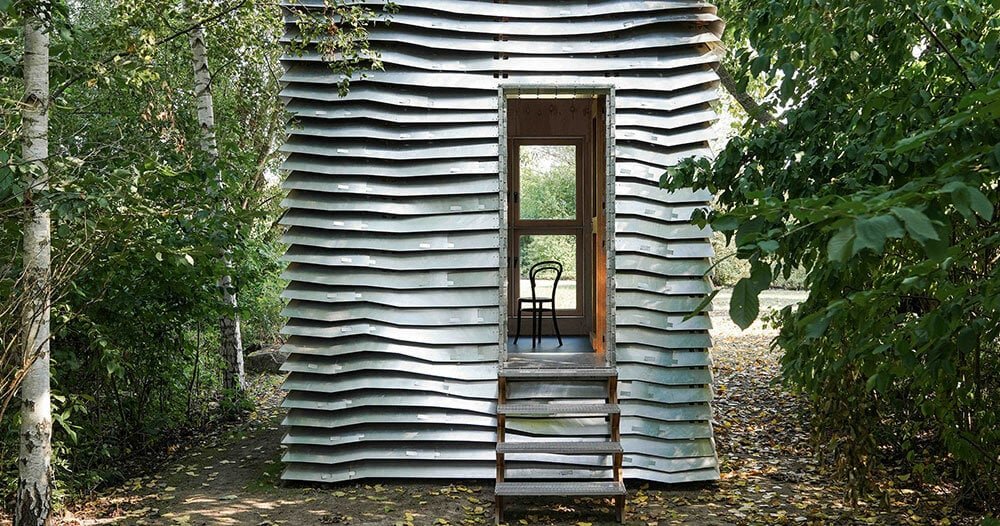

In Northern Germany, the quaint city of Wismar has seen a new evolution of architectural fabrication with this compact Digital House. The team behind this innovation are architects Julian Krüger from the Munich University of Applied Sciences and Benjamin Kemper from the Wismar University of Applied Sciences. While the undulating facade of repurposed aluminum wraps a milled timber structure, the cabin exemplifies an approach to digital construction that is both technologically advanced and resource-efficient.

images © Julian Krüger, Benjamin Kemper

images © Julian Krüger, Benjamin Kemper

the ‘plug-in’ construction of the digital house

With the Digital House, Julian Krüger and Benjamin Kemper merge contemporary design and digital manufacturing techniques. The architects have crafted a sustainable and cost-effective building model that hinges on inventive plug-in construction methodologies. Situated near the Faculty of Architecture and Design at Wismar University, this humble cabin is wrapped in a fluid silver facade –constructed from repurposed aluminum sheets — and a steep, west-facing mono-pitch roof. The structure reaches a height of 6.5 meters (21 feet) atop a footprint measuring 3.3 by 4.9 meters (11 by 16 feet). The interior is illuminated by a continuous strip of windows and four large openings that cut through the facade.

A unique feature of the Digital House is its wood construction system which Julian Krüger and Benjamin Kemper worked to precision-mill from 24-millimeter-thick plywood. This assembly method negates the need for conventional tools or fasteners, enabling a swift and straightforward assembly process requiring just two individuals. This dynamic system not only upholds principles of sustainability but also allows for future disassembly and repurposing. The wooden framework is enveloped by plywood panels on the interior and a vapor-permeable wood fiberboard on the exterior, insulated with environmentally friendly wood fiber. The Digital House is anchored by six ground screws, allowing for both rapid and traceless disassembly, thereby eliminating the need for concrete or extensive groundwork.

the interior is lit by a continuous strip of windows and four large openings that cut through the facade

a facade of laser cut aluminum

The Digital House prototype showcases an intricately designed facade created from recycled aluminum sheets, a parametrically generated assembly which features horizontal elements that gracefully envelop the entire structure. These elements are meticulously tailored to align seamlessly with the building’s openings while expanding outward to embellish the enclosed sections. The aluminum sheets, laser-cut and equipped with essential fastening components, are adjoined to the sub-construction through precise folding. The windows and door adhere to the same plug-in construction principle, and have been crafted through CNC milling of 24-millimeter multiplex panels.

the structure is precision-milled from 24-millimeter-thick plywood

the structure is precision-milled from 24-millimeter-thick plywood

The Digital House is a harbinger of a new era in architectural planning. The team has diligently optimized the building system to accommodate future parametric design strategies. This intrinsic flexibility allows users to tailor the structure’s form, layout, roofing, openings, and facade according to their specific needs, lending an adaptability that’s advantageous for erecting both stand-alone structures and high-density projects within urban landscapes. The project underscores the symbiotic relationship between digital planning, efficient production, and the application of renewable and recycled materials, ultimately contributing to a more sustainable construction ethos.